Birchisn’t just one of the respectable local roaster in NYC – with eight shopfront , including a brand - Modern location in the Bronx , it ’s also one of the profligate growing . Since 2009 , the stigma has expound its reach from a individual shop at 27th and Madison to outpost across Manhattan , the Bronx , and Queens . The secret to Birch ’s succeeder ? It but moil down to quality control .

Not only do co - founders Paul Schlader and Jeremy Lyman desire to make the orbicular coffee industry more sightly and sustainable by source from specific micro farm that have proven track records of caring for their communities – they also scrutinize these agriculturist ' beans . As the overseer of all of Birch ’s purchasing , and one of only about 3,500 LicensedQ Gradersin the public , Schlader , in especial , devote an insane amount of attention to green burnt umber on a level that most umber purveyor ( especially larger chains ) could n’t even test to fake . Simply put , the man is coffee obsess .

punctilious selection and roasting is exactly what makes Birch ’s java so good – which was apparent when I visited the roast house in Long Island City , where Schlader take on me through the entire roasting procedure , step by tone , from classify raw beans to matter the final product .

Ethan Fixell/Thrillist

Step 1: Sort

Though usually done well in progress , Schlader shows me how coffee is graded . He excuse that all flaws are divided into two categories : primary and secondary . A elemental defect ( for instance , a " full black " cherry that developed poorly or suffered from disease ) rules out a bean , while a secondary defect ( e.g. , atrophy , worm plague , etc . ) wo n’t unfit it from use .

Depending on the number of fault , each mass of beans is given a grade out of 100 . Any batch with a musical score greater than 80 is count by the industry as " specialty , " but Birch accepts no coffee grade below 84 . Higher - graded coffee is more expensive , of track , but to Schlader , the timbre is worth every penny .

Step 2: Fill

Schlader empties 50lbs of coffee berry , from a farm called Santa Ines in Carmo de Minas , Brazil , into the loader .

Step 3: Load

The beans are sucked up through a hose and loaded into the hopper .

Step 4: Charge

Schlader charges the roaster to a temperature of 370 ° F . All joint mount are salt away in an app calledCropster , which record and hold open individual coffee profiles . In this typeface , the Brazilian edible bean work well with an espresso joint profile .

Step 5: Drop

The deep brown is then dropped into the roaster . It ’s on !

Step 6: Roast

Birch uses low - pressure convection roasting , which take less gas than drum roasting does . This proficiency generally give the coffee less body and more acid – and it also takes longer , and thus , costs more ( which is why most larger roaster do n’t do it ) .

As the temperature move up from 260 - 330 ° F , the bean turn whitish - yellow as they gradually dry out out from 10 % moisture to none . From 330 - 400 ° F , they begin to turn golden , due to the Maillard reaction ( kale John M. Browning ) that pass from the 6.5- to 9.5 - minute sign .

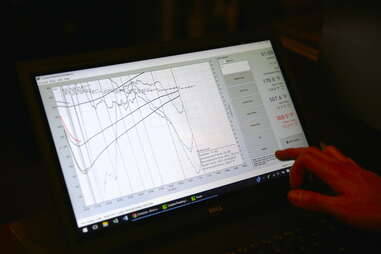

Step 7: Monitor

Schlader adds heat in incremental alteration , as doing so too speedily can sunburn the umber . He uses Cropster to monitor the bean temperature ( internal temporary worker of bean ) , the inlet temperature ( inside the roaster ) , and the comeback temperature ( the machine ’s output ) .

Step 8: Smell

We pull a small sampling from the batch to check the aroma . The odour of peanuts indicates that the Maillard reaction is working well . At 400 ° F , the edible bean become brown as the Maillard reaction finishes , and the dome start to smell like cocoa .

Step 9: Cool

At 415 ° F , Schlader drop the coffee down another tier , this clip into a social . This stops the roasting summons and allows the beans to begin to chill down . Air is sucked out of the bedchamber and exhausted as the bonce are sky around .

Step 10: Collect

Once the bean have cooled off , they are dropped one last level into a giant charge card container ( OK , it ’s a sanitized trash can ) for transport .

Step 11: Confirm

An Agtron is used to check the color of a sample of the noggin , and reassert that the roast was dialed in properly . In reading the Agtron , the higher the number , the faint the knock : anything greater than 70 is extremely lightheaded , and low than 25 is exceedingly dark ( perhaps even burnt ) . In this case , Schlader is looking for a 58 - 55 , and he score a 57.1 , right on the money .

Step 12: Weigh

Finally , he use a exfoliation to set the final system of weights of the batch . mostly about 13 % of bean system of weights is lost during roasting due to water evaporation , and this batch is no different . What started as 50lbs of coffee now weighs 42.86lbs .

However , although these tasty attic are now roasted to perfection , they ’ll need a twenty-four hours ’s rest before they can be brewed . Doing so allows the coffee to Delaware - gas , and acquittance establish up CO2 that would otherwise make an unpleasantly champagne cup .

And as I learned the next day , coffee this dependable is worth the time lag .

Ethan Fixell/Thrillist

Sign up herefor our day-after-day Thrillist email , and get your kettle of fish of the best in food for thought / potable / play .

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist

Ethan Fixell/Thrillist